FEATURE

BOATBUILDING

For Reinauer Transportation Senesco Builds the

First Facet Tugs

Story and Images by Don Sutherland

The world's first Facet Tug, the Ruth M. Reinauer, was delivered by the

Senesco Shipyard in Kingston, Rhode Island, last April. The Ruth's

sister, the Laurie Ann Reinauer, is scheduled for launch at just about

the time this is published. Both vessels represent a new style of ATB

design and construction, insofar as the Facet Tug has not an inch of

curved steel anywhere. It's composed completely of flat steel, multiple

chines taking the place of shaped steel. The result is that a smaller

shipyard can make a large tug -- the Ruth and the Laurie Ann are

116-feet overall, with 4000HP of MTU 16V 4000 M60 power -- at a moderate

cost. The half-year of experience gained between the two launches

revealed only one area for improvement. "Shortly after the Ruth was

delivered," said Senesco project manager George Wu, "it was decided that

performance would be a little better if the pitch of the propellers was

slightly increased." Another specification given by Mr. Wu was the

building time of the newer tug, which he described as "10% shorter" than

the original. Well sure, when

you get to the second one, a lot of the things you had to figure-out for

the first one are already settled. Even progressions like moving the

tug from the construction area to the drydock from which it will be

launched went quicker with the Laurie Ann. Senesco used a brace of

Scheuerle shipyard transporters to move the finished 82-foot tall boat

to its launching point. The trek took five hours for the Ruth -- "we

stopped every few minutes to check everything," said George Wu, "but

following that experience it was more routine with the Laurie Ann,"

whose corresponding journey to the drydock took only about an hour. Also

trimmed was the part that was most challenging on the Ruth, the

construction of tanks within tanks, which make the vessel effectively a

double-hull tug. The operating space inside the tanks was tight for the

workers, and ventilation was always an issue. With the first tug under

their belt, the Senesco workers found the second one all the more

accommodating. Before its first tugs, Senesco had about a decade of

building tanker barges in the 80,000-

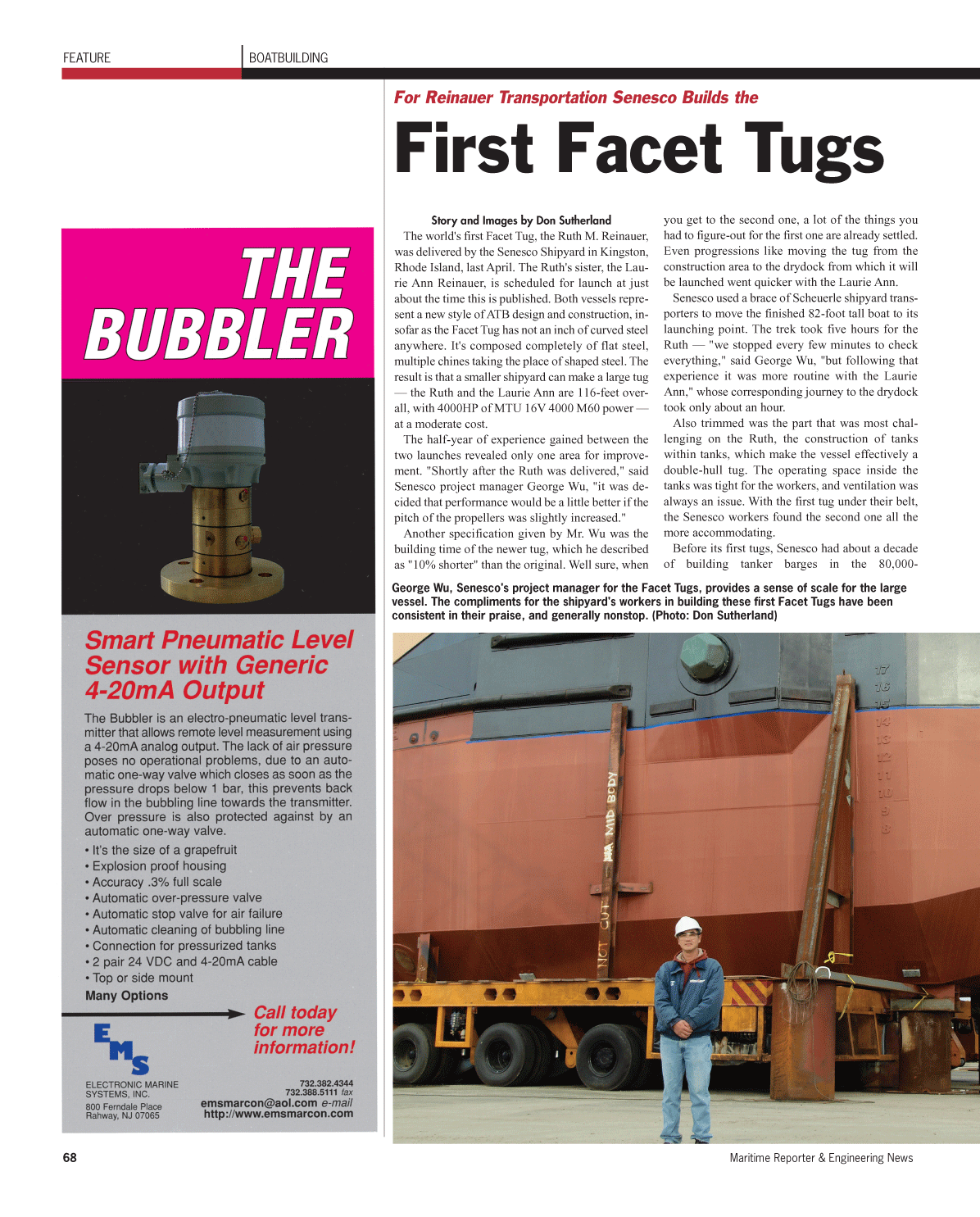

George Wu, Senesco's project manager for the Facet Tugs, provides a

sense of scale for the large vessel. The compliments for the shipyard's

workers in building these first Facet Tugs have been consistent in their

praise, and generally nonstop. (Photo: Don Sutherland)

68

Maritime Reporter & Engineering News

�